Dry Desulfurization and Denitration Technology

Revolutionary exhaust gas purification system that does not use water that will change the world

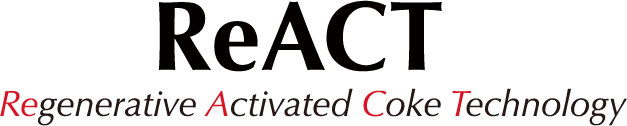

Our dry desulfurization and denitration technology (ReACT: Regenerative Activated Coke Technology) is a new technology that uses activated coke (AC) to purify exhaust gas from a factory or the like. The desulfurization and denitration equipment that uses this technology does not use a large amount of water, unlike other types of equipment.

The dry technology (denitration) was introduced at No. 2 unit of Takehara Thermal Power Station and then adopted at the new No. 1 unit of Isogo Thermal Power Station.

We have accumulated the know-how of the world’s largest scale dry desulfurization equipment.

Engineering Technology of BOP

In a power plant or in plant equipment, peripheral devices guide the most important main body part so that it can be operated safely and optimally. These peripheral devices, such as auxiliary equipment, peripheral equipment and control equipment of a power station, are called the balance of plant (BOP).

The BOP includes a large number of devices and, by properly inspecting each device and reducing maintenance costs, large profit can be achieved.

J-POWER EnTech, Inc. is thoroughly committed to BOP engineering and supports the operation of the equipment in use.

Osaki CoolGen Corporation Slag Transfer Conveyor

AC (Activated Coke) Sales Agent Business

AC (activated coke) is an adsorbent and catalyst that are indispensable in our “dry desulfurization and denitration equipment” for removing harmful substances, or sulfur oxides (SOx) and nitrogen oxides (NOx), in exhaust gases. It is a porous, carbonaceous material with high mechanical strength against abrasion and crushing, and is manufactured from coal.

While activated coke has a low specific surface area compared to activated carbon, it possesses significant features such as excellent desulfurization and denitration performance, high strength and a high ignition point.

The performance of activated coke greatly changes the performance of environmental measures technology for achieving more sophisticated and efficient plants.

We have a stable supply system of activated coke with high strength and excellent desulfurization and denitrification performance. The activated coke used for the equipment can be provided from JM Activated Coke, Inc., a joint venture between J-POWER and former Mitsui Mining Co., Ltd. (currently Nippon Coke & Engineering Co., Ltd.).

Tablet Type

Almond Type

| Activated Coke | Activated Carbon | |

|---|---|---|

| Shape / Diameter |

◆ Tablet / 5 - 10 mm ◆ Almond / 13 x 11 x 8 mm |

◆ Tablet / 5 - 10 mm ◆ Powder |

| Specific Surface Area | 150 - 300 ㎡/g | 1000 ㎡/g |

|

Roga Index (Abrasion Resistance) |

95% | 70 - 85% |

| Raw Material | Coal | Coal etc. |

| Application | De-Sox, De-NOx, De-Hg | De-Hg |